| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : JERO

Model Number : JC18

Certification : SONCAP SABER SGS CNCA FTA QM

Place of Origin : HENAN,CHINA

MOQ : 7 tons

Price : 3000-3150USD/TON

Payment Terms : L/C,T/T,Western Union,MoneyGram

Supply Ability : 6,000 TONS PER MONTH

Delivery Time : 18-22 work days

Packaging Details : Seaworthy Standard Export Package

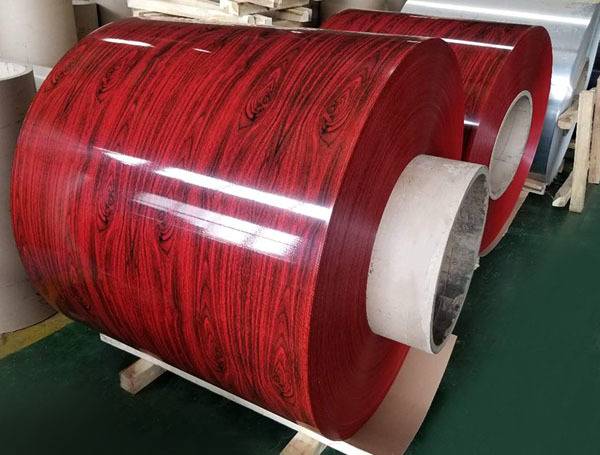

Type : Wood grain aluminum coil

Material : 1050/3004/3105

Coating : PE, SMP, PVDF

Front coating : 15-25 microns/as your request

Back coating : 5+10 microns

Trade Terms : FOB/CIF/CFR/EXW

1.2mm Thickness Imitation Wood Roller Coated Aluminum Coil

Wood texture coated aluminum coil is a decorative building material that replicates the natural

appearance of wood through advanced roller coating or transfer printing techniques.It combines

the durability of metal with the aesthetic appeal of wood, making it ideal for modern architectural

applications.

Company messages

♦ We have implemented standardized processes to enhance work efficiency, reduce confusion,

minimize errors, and boost overall productivity.

♦ A comfortable and well-lit work environment, combined with a reasonably arranged office layout,

fosters a positive work attitude, healthy interpersonal relationships, and sustained team growth

motivation, while enhancing team cohesion and a sense of belonging.

♦ The left 1 is me ^ ^ , we expect the cooperation with your company.

1) We are professional color coated aluminum material manufacture factory, own 3 production

lines for coil, 2 lines for sheet, the Max Width 2700mm.

2) We follow clear internal management and standardized processes to keep our production smooth,

efficient, and well-organized.

3) Mainly products: color coated aluminum coil

wood grain coated aluminum coil

stone texture coated aluminum coil

Al-Mn-Mg roof aluminum coil

mirror finish coated aluminum coil

At the same time, we can produce curtain wall aluminum veneer, aluminum honeycomb panel,

heat transfer printed aluminum coil.

Inspection and Testing Measures for Color Coated Aluminum Coil

1) We test the bending and hardness property for every batch raw material, make sure the Alloy

Temper can meet customer’s requirement.

2) During the production process, we use online inspection systems to monitor key parameters,

such as coating thickness, uniformity, adhesion.

3) Before delivery, we will select samples to test, including grid testing, impact testing, and bending

testing. For some special products, we will carry out some chemical testing.

4) We have MTC for every batch product, convenient for tracking and confirmation. Test records

are kept by our laboratory staffs.

Ocean Shipping

1) We use cushioning materials between the coil and wall, and tighten everything with specialized

lashing straps.

2) we place non-slip wooden blocks under each coil to prevent any movement during the shipping.

3) It has the waterproof layer inside the package, we also put many desiccants in the container,

to protect the cargo from moisture

Key Features

• Realistic Wood Effect: High-definition patterns (e.g., teak, oak, walnut) with textured finishes.

• Lightweight & Strong: Aluminum core (density: ~2.71g/cm³) ensures structural stability with

minimal weight.

• Weather Resistance: PVDF (for outdoor) or PE (for indoor) coatings provide UV protection,

corrosion resistance, and a lifespan of 10-20 years.

Recommended Thickness by Application

| Application | Recommended Thickness | Rationale |

| Interior ceilings/walls | 0.5mm-0.8mm | Lightweight, cost-saving |

| Low-rise building facades | 1.0mm-1.5mm | Basic wind load requirements |

| High-rise/coastal facades | 2.0mm-3.0mm | Withstands strong winds/salt spray |

| Furniture/cabinet panels | 0.4mm-0.7mm | Easy fabrication, smooth finish |

| Outdoor canopies/railings | 1.2mm-2.5mm | High weather resistance needed |

Our Company Advantages and Production Range

Advanced Equipment

• German SMS Group fully automated coating lines with ±0.01mm thickness precision,

Line Speed: 120m/min (20% faster than industry average)

• MES system enables real-time production monitoring with ≥99.3% product qualification rate

• Multi-spectral imaging detects micro-defects as small as 0.02mm² with 99.8% recognition accuracy

| Thickness Range | 0.20 - 5.0mm |

| Width Range | Max. 2700mm |

| Alloy | 1050,1060, 3003, 3004,3105,5052 |

| Paint System | PE, SMP, PVDF |

| Color Options | RAL color or as the sample |

|

|

1.2mm Thickness Imitation Wood Roller Coated Aluminum Coil Images |